What are buyers looking for in forklifts today – and why?

Cat® Lift Trucks looks at the key challenges and solutions shaping modern forklift development.

As any materials handling market trend report will tell you, the demand for forklifts continues to rise rapidly. Expansion of construction and manufacturing in our fast-changing world accounts for much of it. However, analysts often point to the growth of e-commerce as the prime driving factor.

Online shopping doesn’t just require movement and handling of large volumes of goods: it needs them to be moved faster than ever. But of course, every other business sector also wants its operations to be quicker and more efficient. Lift truck advances should increase productivity while reducing costs, to keep businesses profitable and competitive.

In addition to speed, efficiency and cost-effectiveness, customers also want sustainability. The good news is that this comes as part of today’s reshaped forklift package. Our summary below highlights examples of forklift developments helping to save time, space and money.

Lift trucks saving time

High power is essential to rapid lift truck operation. Traditionally, diesel forklifts were seen as the strongest option. Now, electrics can compete in the same applications. For the greatest assurance, most Cat® electric counterbalance trucks offer the PowerBurst feature (optionally or as standard). It gives an extra burst of torque when needed to maintain ramp speed or to accelerate strongly.

Importantly, maximising productivity is not only about power ratings and top speeds. It’s about optimising speed while avoiding collisions, spillages and overturns. See our article on how to speed up materials handling. Intelligent cornering control is amongst the motion-optimising systems found on many Cat electric counterbalance, reach trucks, stackers and power pallet trucks. Another advance is the 360-degree steering option. It allows you to turn and move the opposite way in one smooth, non-stop manoeuvre. This saves time, while reducing the risk of spilling loads. Systems controlling the speed and consistency of hydraulic actions in load handling similarly help to maximise work rates.

Lift trucks can also save time by spending less of it in the service and repair bay. Robust construction with inbuilt protection of components is a good starting point. Easy access features, for quick and simple servicing, help too. A further trend is that of fitting forklifts with telematic devices, so they can be remotely monitored. This technology, along with analysis of the data gathered, optimises maintenance timing and fleet utilisation. See our article on telematics. We should also mention the increasing popularity of lithium-ion (Li-ion) batteries, which minimise battery-related downtime.

Accidents are another source of downtime, and of extra costs, which we will come back to later. We’ve already mentioned aids to optimising speed. Lighting is an additional area in which we are seeing improvements. LED lights improve both the driver’s vision and the forklift’s visibility. Awareness of a lift truck’s presence is now commonly enhanced by coloured light spots and/or lines projected onto the floor.

Forklift design increasingly recognises the importance of making the operator feel comfortable, contented and in full control. Quite simply, a happy operator will perform more productively. The same ergonomic design considerations will also reduce time lost to sickness absence. We have explored the essential topic of user experience in previous articles.

Here are a few examples of what improving user experience looks like in Cat lift trucks:

- Responsive Drive System (RDS) and SmoothFlow load-sensing hydraulic system on Cat electric counterbalance trucks up to 5.5 tonnes

- Choices such as Palm Steering, double pedal system and dual joysticks on many Cat electric counterbalance and reach trucks

- Unusually low (for a heavy electric forklift) seating position on Cat 6.0 to 12.0 tonne electrics, to minimise the need for climbing

- Class-leading ergonomic emPower tiller head on Cat pedestrian and platform power pallets and stackers

- Electrically adjustable damping on Cat platform stackers

- Electrically adjustable floor height on Cat sit-on power pallet trucks and stackers

Lift trucks saving space

A warehouse operation’s efficiency and profitability can be increased by making fuller use of its horizontal (floor) and vertical space. In other words, maximising its storage density. Designers have reshaped and re-engineered various categories of lift truck to allow use of narrower aisles and taller racking. At its extreme, this results in very narrow aisle (VNA) equipment like the Cat man-up turret trucks and man-down VNA trucks.

More conventionally, the space taken up by aisles is often reduced by deploying compact power pallet trucks and stackers. To date, pedestrian and – for higher productivity – platform versions have dominated in these applications. While continuing to develop these, Cat Lift Trucks has led the way in developing stand-in power pallets and stand-in stackers. They can work in narrower aisles, and lift to higher levels, compared to platform models. They also make every operation faster. The same can be said for Cat sit-on stackers and sit-on power pallets. To find out more about how stackers can boost your warehouse operation, see our article on why you should choose a stacker.

For even greater storage density, Cat Lift Trucks offers the latest in telescopic fork stackers (in stand-in and sit-on versions). With these, you can immediately increase your warehouse capacity by up to 30%. That’s because you will need only half as many aisles. From each aisle, telescopic forks will reach into your racking to stack and retrieve loads at two pallet depths.

Whatever lift truck you choose, optional feature specifications are a great way of fitting and equipping it perfectly for your workspace and application. Our article on the importance of options includes examples of how a forklift can be specified to make best use of your space.

Lift trucks saving money

Not all technological and design developments make an obvious difference to the shape of the lift truck. Some of them lie deep within the powertrain. For example, electric motors are becoming more and more energy efficient. (And engines are becoming more fuel efficient.) There have also been great leaps in battery efficiency, especially with the advent of Li-ion technology. Meanwhile, advances in electronic control and programming allow further power efficiencies. The result is lower energy bills.

As we have already mentioned, trucks can be designed and built to need less servicing and repair. Time is money – whether that’s forklift downtime or the cost per hour of a service engineer’s labour. Replacement parts cost money too.

We’ve also talked about features that reduce the risk of accident-related expenses – including downtime, damage and compensation. Designing for ergonomics and comfort saves money too, by preventing sickness absences related to stress and strain. Our article on the health benefits of electric forklift trucks reinforces the financial and productivity advantages gained by looking after your operators.

Improvements in lift truck qualities and capabilities almost inevitably have an impact on their purchase price. At the same time, however, they can save you money overall through a lower total cost of operation (TCO). Our article on how to save money on forklifts summarises the many ongoing costs you should consider when comparing trucks.

Forklift electrification

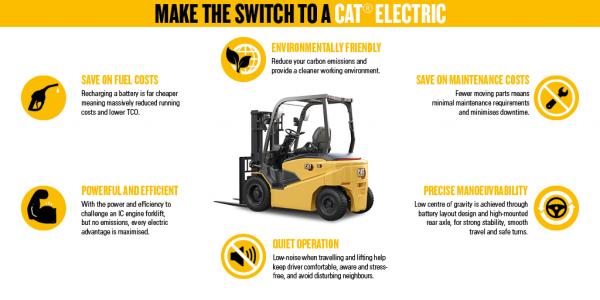

The most obvious trend in lift truck buying habits today is due to electrification. LPG and diesel forklifts still have important roles, and we continue to improve their performance in all respects – including sustainability. However, most forklifts today are going electric.

As our online guide to forklift electrification explains, electric lift trucks are not just environmentally friendly. They also tick all of the other boxes above. You don’t have to choose between environmental responsibility and business success.

We all have a duty to cut carbon emissions. Using efficient forklifts helps reduce society’s dependence on fossil fuels. By choosing lift trucks which reduce accident risks and are resistant to damage and wear, we also avoid material waste. This, in turn, means less energy is needed – and carbon emitted – in manufacturing replacement parts and trucks. In addition, lift trucks designed to maximise storage density can limit the amount of energy we spend on heating empty warehouse space.

For further insights into materials handling trends, visit the Cat Lift Trucks blog https://www.catlifttruck.com/blog.