By Gian Schiava

A forklift truck is basically a transportation device with a mast and forks at the front and a counterweight at the back. There are many different options available but the handling device essentially stays the same. Gian Schiava explores the variety of forklift attachments that cater for specific operational requirements and may be added to help improve your materials handling versatility and performance.

A forklift attachment can be fitted onto a new machine or as a retrofit to suit a new materials handling need

. Basically it is a device, other than conventional forks or load backrest extensions, which is mounted either as a permanent or removable fixture on the mast of the forklift to help handle a load.

The attachment may be removable so that it can be taken off at any time which in practice gives advantages such as:

- Versatility - you can increase the versatility of your forklift truck as it can be equipped to perform different handling tasks.

- Increased productivity - your forklift will be better able to handle a specific load and can therefore carry out work more quickly.

- Enhanced safety and decreased damage costs - handling a load correctly means less risk of damage to the load.

There are many choices of forklift attachments available on the market and literally hundreds of different configurations and designs. Below are the most popular.

The Sideshift:

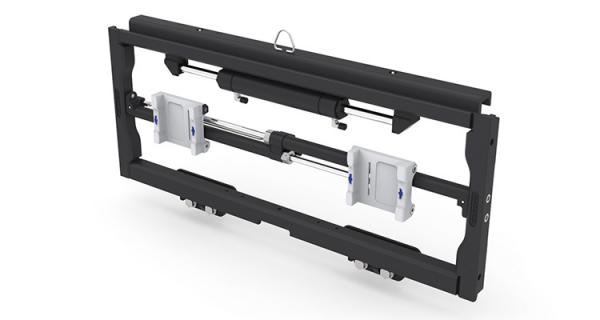

The sideshift is one of the most common forklift attachments used for materials handling tasks today. In fact, many forklift truck manufacturers offer it as standard. A sideshift allows you to shift the forks from left to right (or the other way). It allows you to pick up the load more quickly, as perfect alignment of the truck is no longer necessary and therefore helps increase productivity - as your forklift will be better able to handle a specific load, you can bet that the job will be done faster. Sideshifts come in hook-on and integrated versions. The first is removable, offering flexibility, but the integrated one reduces the capacity loss which you normally get when an attachment is added.

The Fork Positioner or Fork Spreader

A similar advantage is delivered by the fork positioner or fork spreader. This enables the driver to hydraulically increase or reduce the gap between the forks. It enhances speed, like the sideshift, but has the added benefit of being able to adapt to picking up different-sized pallets and odd-sized objects.

The many other options to customise forklifts are mostly about gripping containers, rolls, bags and other types of loads that need to be transported safely in the warehouse. Here are some examples:

- Paper roll clamps - These devices handle different-sized paper rolls for industries such as printing, paper manufacturing and other paper-related products. Importantly, they can be fitted with automatic pressure controls to avoid damaging the paper roll.

- Pushers or push/pull devices - These are used for loads that are placed on slip sheets instead of wooden or synthetic pallets. The advantage comes from cost savings relating to use of inexpensive slip sheets due to decreased maintenance costs, less storage area needed and the avoidance of stock damage due to old pallets. Slip sheets are often used with bags (e.g. cement, seed or grain), packaged foods, dairy products, fruit and corrugated boxes.

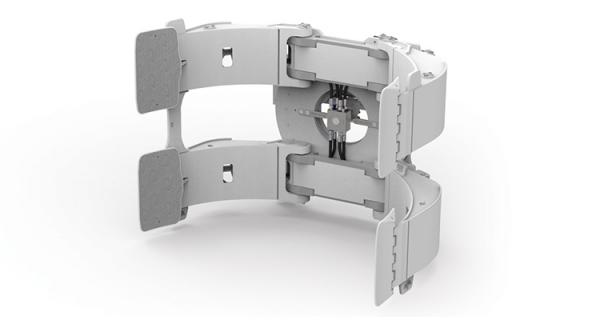

- Clamps and rotators - To handle larger or square-shaped objects, you can customise with a clamp or a rotator. These types of forklift attachments can be seen in industries like bricks and blocks, beverages, paper, fabrics, appliances and other electronics. They can also be used to handle fragile goods.

Attaching is not the same as adding

However, there are consequences to custom forklifts as enriching your lift truck with a special attachment can affect it. Possibly the biggest downside to be aware of is that the centre of gravity will be affected in a negative way, resulting in a reduced load capacity. However, it could also have some impact on stability, due to extra weight on the front of the forklift.

In practice this means you could end up needing a forklift truck with a higher load capacity than you would need without the attachment. A stronger truck often means a heavier counterweight as well, thus eliminating the risk from the (slightly) reduced stability.

In order to determine the right configuration for your forklift, the best advice is to discuss your needs in detail with the forklift truck supplier.

In the case of an electric forklift, there is an additional concern, as heavy use of a forklift attachment may considerably shorten the battery’s lifetime and will therefore influence battery choice. Even the hydraulic system may need adjustment, as the battery, hydraulic pressure, tube sizes and attachment capacity all need to be carefully aligned. Professional materials handling equipment dealers work closely with battery suppliers on this issue, to ensure productivity and also to minimise energy costs.

Finally, bear in mind that using forklift attachments also means the lift truck drivers need additional training to become competent in fitting, operating and removing the devices.

Multi-tasking, multi-skilled manual handling machine

By using Forklift attachments you can transform your forklift truck into a multi-skilled machine and if properly selected, will enhance your warehouse operations. The productivity gains from a custom forklift should outweigh the additional costs of investment, maintenance and truck adjustment, provided all the possibilities are carefully considered.

If you would like to read the unabridged article by Gian Schiava please visit Eureka, the online magazine for the materials handling professional: http://eurekapub.eu/materials-handling/2016/09/08/1000-ways-tailoring-f…