Question: Why does it matter that the Cat® emPower tiller head is the most ergonomic on the market?

Answer: Because that’s a key to higher output and more profit.

A tiller-operated warehouse lift truck’s tiller head is the all-important interface between the operator and the machine. Its design and operating characteristics are crucial to productive and safe control of steering, driving and load handling.

An ergonomically designed tiller head is easier and more comfortable to use. That means less tiredness, fatigue, stress and strain – and lower risk of sickness absence due to ailments such as RSI (repetitive strain injury). It also enables more precisely controlled operation, so work rates can be increased while avoiding the expense of accidents.

With those priorities in mind, Cat® Lift Trucks research and development teams have invested huge efforts into perfecting every detail. The resulting patented emPower tiller head is now standard on all Cat tiller-steered warehouse trucks. That includes pedestrian and platform stackers, power pallets and double pallet handlers. Depending on model choice, it comes with a choice of three steering types – as explained in a separate article.

Let’s have a closer look at the emPower tiller head’s advantages…

Handle

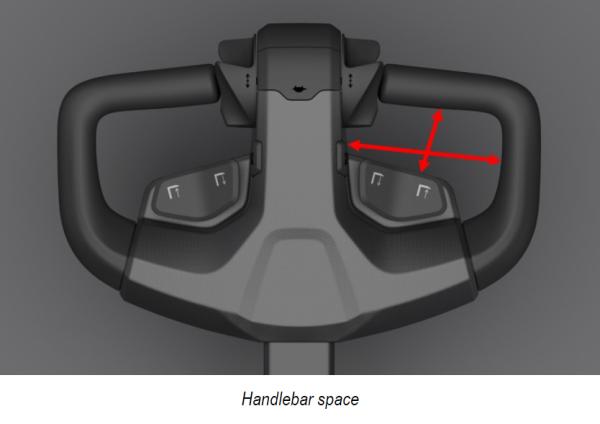

The handle’s surface covering material has a soft, high-comfort feel and gives a good grip. Its overall shape and cross-sectional profile have also been optimised for comfort. The design provides plenty of space for even the largest and most thickly gloved hands to move freely. Crucially, the distance between the hand and the lift/lower buttons has been calculated for optimum ease of use. The unique design formula which makes this possible has been patented. Whatever the tiller’s position, including vertical, these controls can still be easily reached.

Lifting and lowering buttons

Rocker buttons for lifting and lowering are positioned on both sides of the tiller head, allowing left-handed or right-handed use. Details such as their angle in relation to the operator’s hands have been carefully designed. Their arrangement takes into account the difference in length between the index and middle finger. Combined with the patented optimum distance design, it means users need only lift those two fingers to operate the controls.

In addition, the rocker buttons are larger and have a longer stroke than conventional versions. This minimises the chances of inaccurate button presses and gives finer control of lifting and lowering speeds – even when wearing gloves.

Drive speed and brake controls

Direction, drive speed and braking are governed by butterfly-type controls. These can be turned forward and backward with little effort. There is one of these on each side of the tiller head, so they can be operated with either hand. Again, they are designed to work well for all hand sizes and for use with or without gloves.

The butterfly wheels have seven large grip surfaces for the operator’s thumbs. With a choice of seven positions, the operator can always find the one that’s most comfortable and avoid straining his or her thumb. The range of rotation in the controls is set to prevent overstretching of the thumb but to allow precise speed adjustment.

Releasing the control or rotating it in the opposite direction applies the brakes and transfers energy to the battery through regenerative braking. The efficiency benefit is greatest if Li-ion batteries are chosen, as these optimally absorb the regenerated energy.

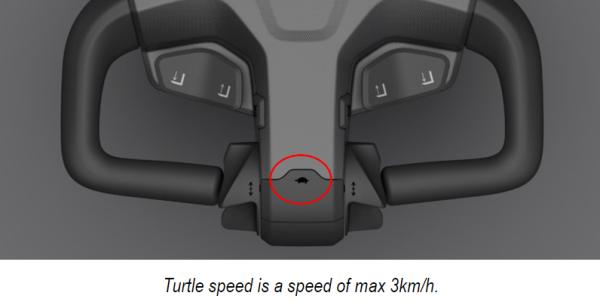

Turtle button and tiller up drive

Tiller up drive is standard or optional, depending on model, on the pedestrian and folding platform trucks. It allows a truck to be manoeuvred through the tightest spaces with its platform (where present) folded in and its tiller arm vertical. Pressing the turtle button permits travel with speed limited to a maximum of 3 km/h.

When the tiller arm is vertical, the handle’s design still enables operators to create enough torque for turning. On models with power steering, manoeuvring is even easier.

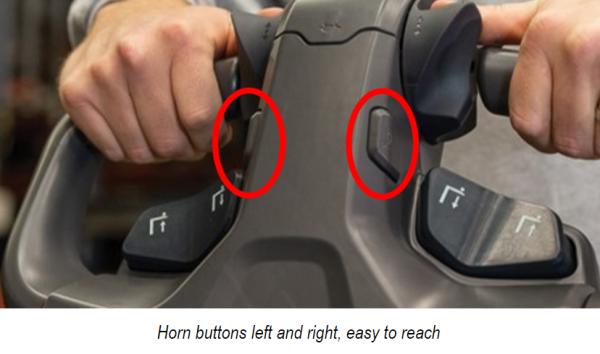

Horn buttons

There are two large horn buttons. These can be quickly and easily reached and operated by either hand whenever a warning is needed.

Belly safety button

This feature is for situations where the operator is in danger of being trapped by his or her reversing truck. On pressing the emergency belly safety button, the truck instantly moves a short distance forward.

User-friendly – and durable too

In addition to its ergonomic, safety and productivity advantages, the emPower tiller head offers high durability. This enhances its cost-saving and profit-maximising benefits. Designed for resilience in all weathers and environmental conditions, it’s protected to IP65 standard. It’s also structurally reinforced to withstand impacts from falling goods. Meanwhile, keypads and displays have been located away from the tiller head to minimise the risk of damage.

Empower your operators and business

Find out how Cat tiller-controlled warehouse trucks can boost the performance of your operators and business. Click here to explore our lift truck range.